AI deep learning re evaluation system - AOI+AI re evaluation upgrade

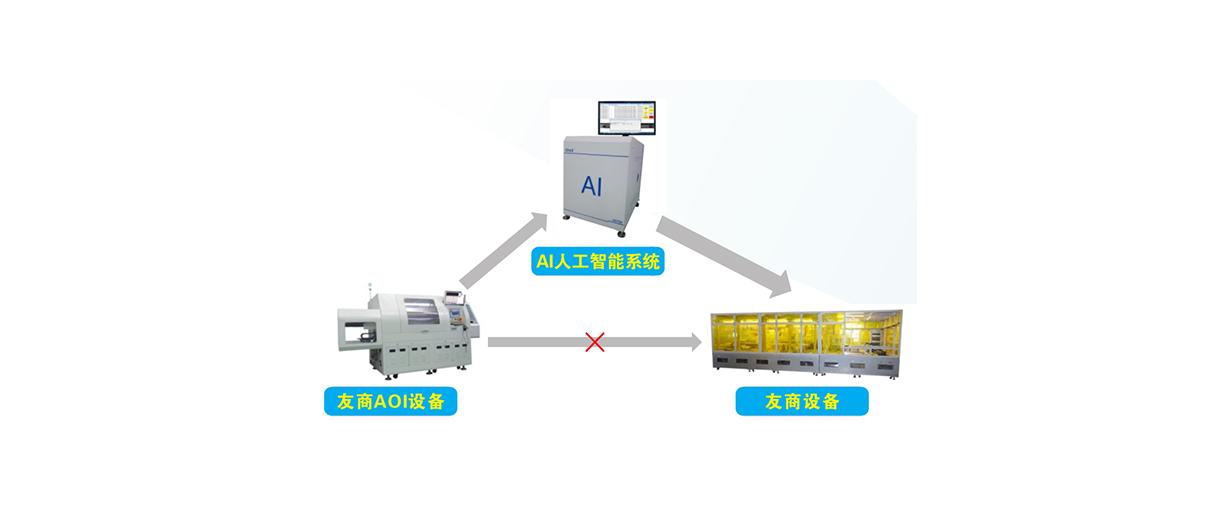

At present, most of the existing traditional AOI detection equipment in the market does not have AI deep learning function, and generally has pain points such as high false alarm rate, which cannot achieve automated production and low production efficiency. The AI artificial intelligence system communicates with friendly AOI devices through the network, and based on the detection results of friendly AOI devices, uses a deep learning based AI artificial intelligence system for re evaluation to reduce false alarm rates and improve detection accuracy.

Design scheme

Usage effect

1. Reduce the workload of manual re evaluation, save labor costs, achieve automated production, and improve production efficiency and benefits;

2. Improve detection accuracy, avoid instability caused by manual re evaluation, and ensure efficient and stable detection of defective products;

3. AOI+AI re evaluation upgrade and transformation do not require hardware modification of the production line, have minimal impact on production, and can achieve rapid integration.