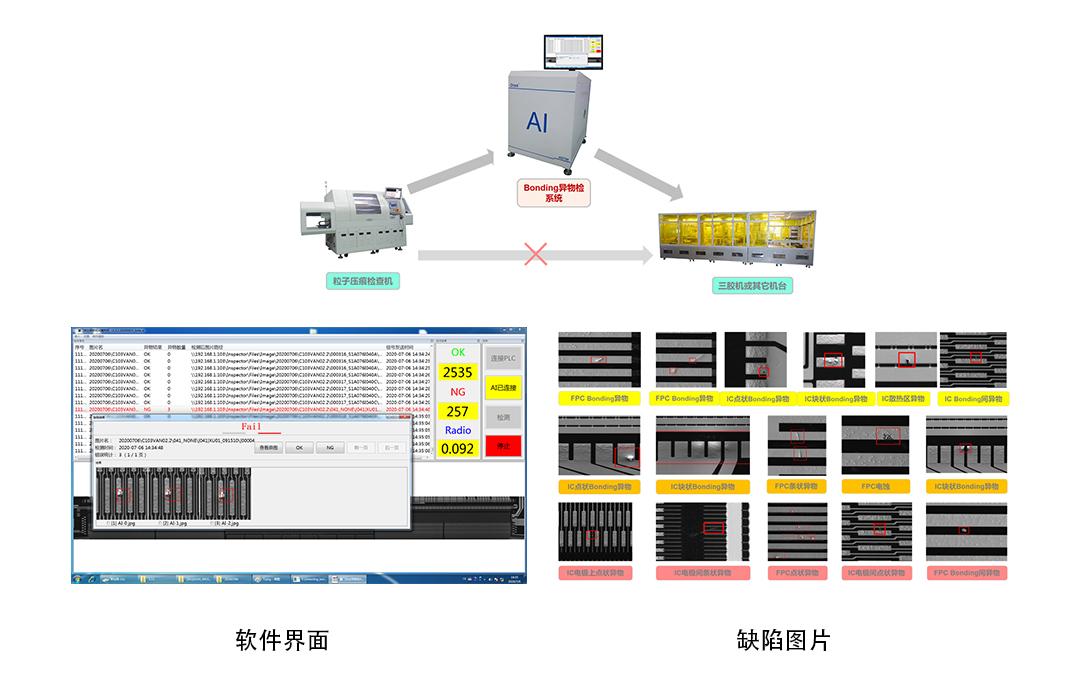

AI Artificial Intelligence System - Bonding Foreign Object Detection System

The bonding foreign object detection system is used to detect foreign objects in the pictures of friendly particle indentation inspection machines. Due to the inability of particle indentation inspection machines to detect defects such as scratches, foreign objects, and fragments, it may miss detection. Our bonding foreign object detection system can detect the above defects and improve the yield rate of the production line.

|

Project |

Performance index |

|

Equipment usage |

Automatic inspection of pressed foreign objects on IC/FPC Bump/electrodes, between Bump/electrodes, and outside of Bump/electrodes (in the pressed area) |

|

LCD size |

Edge detection: can detect products of all sizes, with detection areas including Source, Gate edge IC, and FPC lamination area |

|

Detection speedTT |

The average processing time for one image is ≤ 2S; If a product has 6 original images, the processing time is ≤ 12 seconds |

|

Detection accuracy |

Detectable foreign object size ≥ 4.5 μ m; It depends on the accuracy of the particle indentation inspection machine |

|

Detection rate |

Detection rate: ≥ 95% (detection rate=number of foreign object defects detected by AOI/total number of foreign object defects), depending on the accuracy of the particle indentation inspection machine; |

|

Direct rate |

Direct rate: ≥ 95% |

|

Repeatability of foreign object detection |

Repeatability of foreign object detection ≥ 95% (continuous detection of the same product 30 times) |

Design scheme