AI Artificial Intelligence System - Defect Image Classification

Classify defects detected by friendly AOI equipment using AI for quality traceability. The classification accuracy reaches over 99%.

Usage effect

1. Implement automatic defect classification and statistics;

2. Analyze the sources of defects based on statistical results, guide process improvement directions, and improve production line yield.

Product features and technological advantages

1. Automatic image classification for easy data traceability and user queries;

2. Easy to use, convenient to configure, and capable of rapid secondary development to meet the personalized needs of different customers;

3. Reliable equipment, long barrier free working time, fast response+high-quality after-sales service.

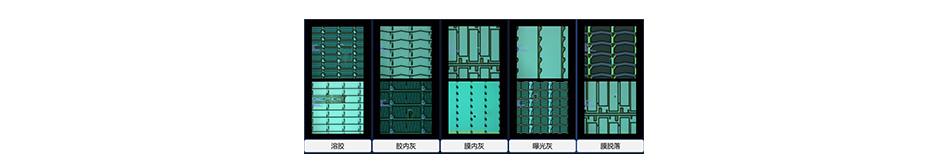

Defect legend