The TFT-LCD edge inspection machine is developed and produced by Fuxin Optoelectronics. Based on machine vision and AI artificial intelligence technology, the TFT-LCD edge inspection machine integrates optics, mechanics, electronics, software, and algorithms. It is mainly used for automatic detection of edge defects in the TFT-LCD production process, achieving machine replacement. In practical applications, suspected defect areas are extracted from the edge sample images of TFT-LCDs after image processing, and judgment criteria are established to effectively eliminate interference. The types of defects such as edge extension, shell, edge collapse, and corner collapse are successfully determined, and the criteria are established to avoid repeated judgments and detect multiple defects simultaneously.

|

Project |

Performance index |

|

Detection area |

Detect defects on 2-4 edges of the TFT-LCD |

|

Testing items |

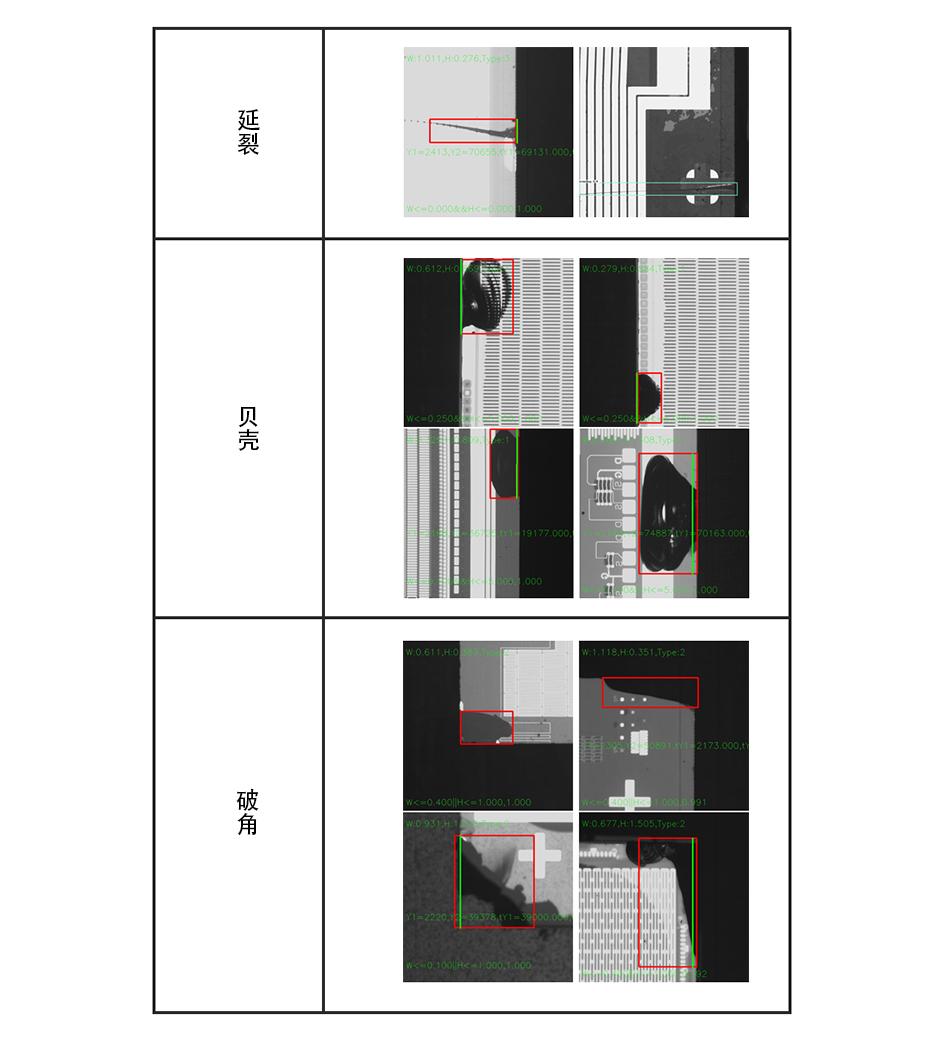

Defects detected include: cracks, shells, and broken corners |

|

Over inspection rate |

<5%, with an average misjudgment of<2 images/piece |

|

Detected Defect |

Extended crack: width>0.1mm; Note: Width refers to the depth from the edge of the glass inward, while length refers to the width, the same applies below; |

|

Shell shaped defects: width>0.1mm or length>0.1mm; Report when either length or width is met; |

|

|

Broken corner defect: width>0.15mm or length>0.15mm; Report when either length or width is met; |

|

|

Product throughput rate |

≥90% |

|

Loss inspection rate |

<0.1% (missed detections/actual number of defects) |

|

Detection algorithm |

Using traditional algorithms and AI deep learning algorithms to achieve accurate identification of product defects and background filtering. |

|

Structural Requirements |

There are two modes of offline inspection and AAS machine serial inspection: Offline inspection: Personnel are fed onto the platform, and their arms are moved from the platform to the AOI detection position for inspection; AAS machine serial inspection: The automatic assembly machine AAS is connected in series, and the machine automatically takes materials and moves them to the AOI inspection position for inspection. |

Defect image